Pálicí stroje

ZEUS NEO

- moderní, spolehlivé, vysoce výkonné zařízení

- pro plazmové a autogenní řezání

- použití v těžkých provozech

- maximální přesnost polohování hořáku

- vysoká pojezdová rychlost

Zaujal vás tento produkt?

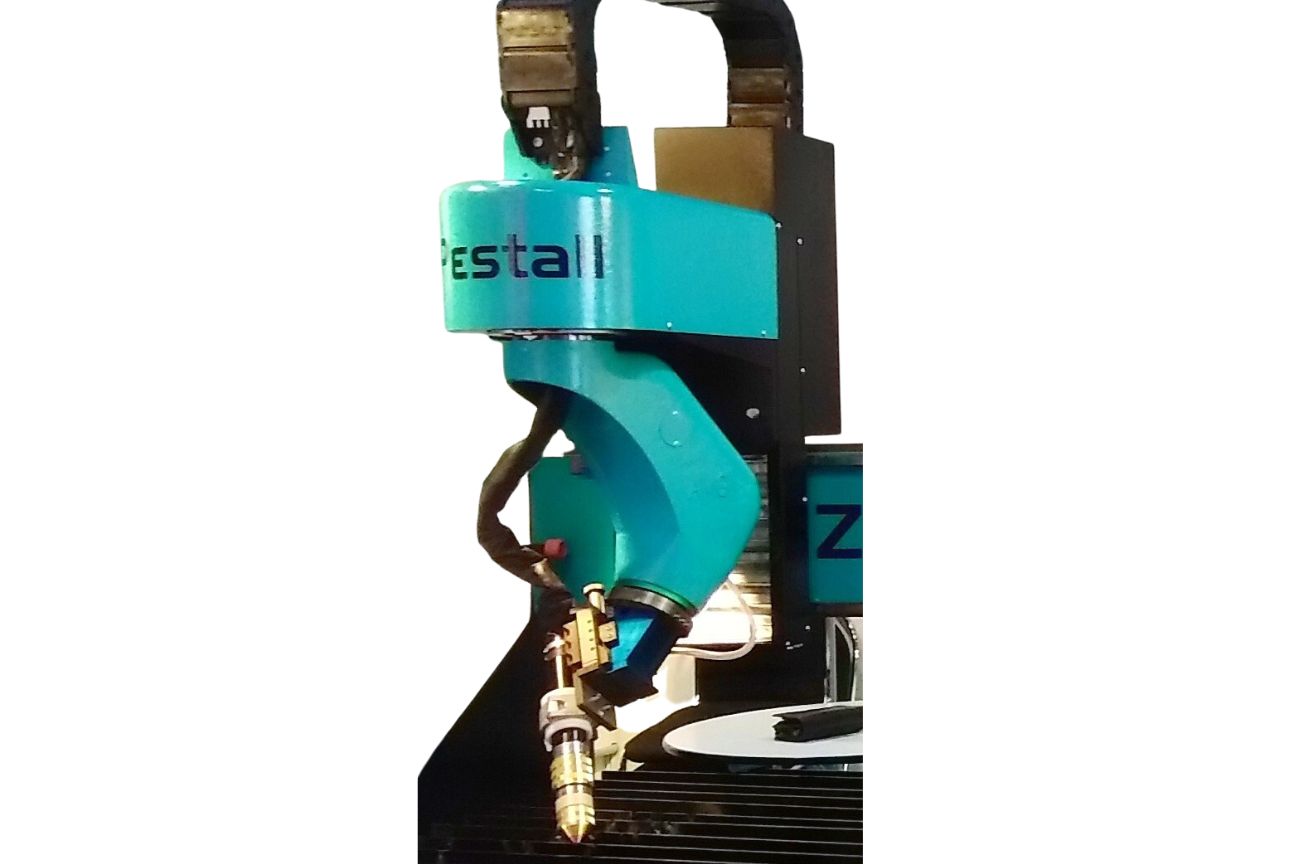

ZEUS MAX

- stroj v nadstandardní výbavě

- suport s velkou nosností schopen nést speciální technologie

- pro plazmové a autogenní řezání

- použití v nejtěžších provozech

- pro zpracování největších formátů plechů

- řezání ve 3D

Zaujal vás tento produkt?

TITAN

- primárně pro plazmové řezání

- vysoce výkonné pohony

- vysoká přesnost polohování

- maximální pracovní rozměr stroje 2000×6000 mm

- doplňkové technologie – navrtávání, značení, popisování

Zaujal vás tento produkt?

ARES

- moderní, ekonomické, spolehlivé zařízení

- pro řezání kyslíkem i plazmou

- pro běžné dělení materiálu

- použití v jednosměnném provozu

Zaujal vás tento produkt?

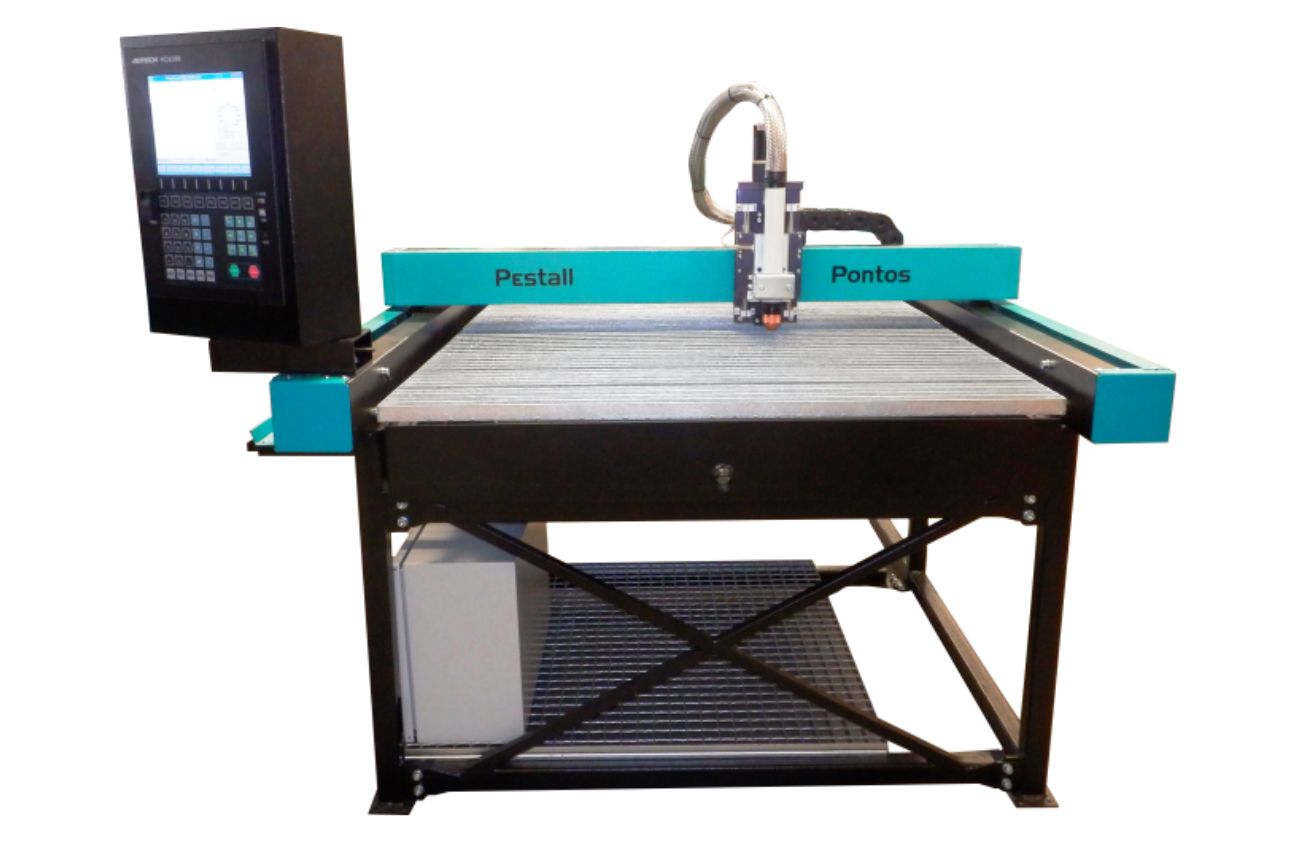

PONTOS

- pro plazmové řezání bez potřeby odsávaní

- vybaven vodním stolem

- maximální pracovní rozměr stroje 1250×2500 mm

- tloušťka řezaného materiálu do 30 mm

Zaujal vás tento produkt?

Zajímá vás jiná kategorie?

Vyberte si.